Energy efficiency and CO₂ neutrality

Our production facilities are equipped with energy-efficient machines that minimise energy consumption. We also rely on comprehensive energy monitoring to make production CO₂-neutral. CB TEC's production facility can be described as CO₂-neutral in terms of water and electricity.

We generate clean energy for our sites with a powerful photovoltaic system (2.7 MW). A 200 kW battery storage system supports the efficient use of energy and ensures a stable supply at CB TEC.

At the same time, we are promoting electromobility: our vehicle fleet is gradually being converted to e-mobility and employees can charge their electric cars free of charge at the workplace.

Heating and cooling via the Alois Müller energy centre

The energy centre houses a combined heat and power plant (CHP for short) with 220 kW of electrical power and 250 kW of heat, which is operated exclusively with green gas. This means it is also CO₂-neutral. During longer periods of cold weather, a wood pellet boiler fuelled with renewable raw materials provides additional heat. A gas boiler fuelled with green gas is available as a back-up for redundancies and peak loads. The systems feed their heat into a 100,000-litre buffer storage tank. The heat can be stored here for several days. However, it is not only the heat generated by the pellet boiler fuelled with renewable raw materials and the CHP powered by green gas that flows into the large water tank: surplus solar power can also be stored here in the form of heat. A simple heating rod heats the water.

Conserving resources in production

Water recovery and recycling

Our water treatment plant in CB TEC's production facility recycles all production water. This is continuously purified and fed back into the production process - a 100% closed cycle.

Nitrogen storage and heat recovery

At CB Kollinger, we use a self-producing nitrogen system with 18 bundles of nitrogen storage for energy storage. The waste heat from the compressors is also recovered. These measures reduce energy consumption and minimise emissions.

Powder coating without waste water

Our powder coating plant at CB Kollinger is completely self-sufficient and produces no waste water. We are therefore setting new standards for sustainable production processes.

Our products - sustainable and durable

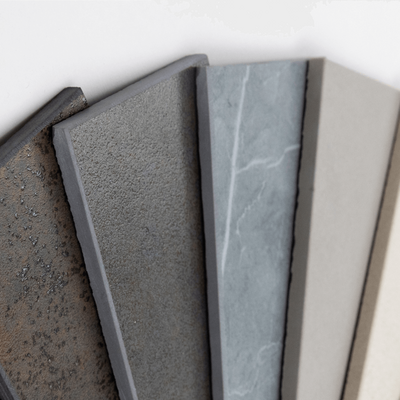

Our products epitomise the CB GROUP's commitment to sustainability and durability - from our fireplace solutions to high-quality natural stone and ceramics. The materials used, including ceramics, natural stone and glass, come from environmentally friendly production and are an expression of our commitment to sustainable quality.

Our fireplaces in particular are an example of sustainability in the fireplace industry. They combine impressive aesthetics with advanced combustion technology for energy-efficient and low-emission operation.

Sustainable innovations at CB Kollinger

Energy audit in accordance with DIN EN 16247-1 - Our basis for sustainable efficiency

Our energy audit in accordance with DIN EN 16247-1 enables us to analyse energy flows, identify potential savings and implement targeted optimisation measures.

- Data-based decisions: Transparent insight into our energy consumption to increase efficiency.

- Focus on sustainability: Targeted measures reduce energy consumption and CO₂ emissions.

- Cost efficiency: Long-term savings through optimised energy strategies.

- Responsibility and innovation: A proactive contribution to climate protection and resource conservation.

Efficient compressed air solution with intelligent control

Our centralised compressed air compressor system shows how technological innovation creates ecological added value.

- Higher-level control: Optimum adjustment to the compressed air requirement minimises energy consumption.

- Heat recovery: Waste heat from the compressors is used to heat water.

- Reliability: Modern monitoring ensures trouble-free operation and extends the service life of the system.

- Cost efficiency: Lower operating costs thanks to optimised energy and heat utilisation.

- Environmental friendliness: Reduction of the CO₂ footprint thanks to the dual utilisation of energy.

CO₂-reduced steel - responsibility in production

By partially using CO₂-reduced steel, we actively contribute to reducing emissions.

- Sustainability: promoting resource-saving processes for a greener industry.

- High quality: The steel combines durability with a low ecological footprint.

- Innovative edge: With this material, we are setting standards for environmentally friendly developments in production.

Sustainable self-supply with nitrogen from renewable energy

CB Kollinger utilises surplus solar energy to produce its own nitrogen in its own innovative nitrogen generation plant.

- Energy storage: surplus solar power is converted into nitrogen gas and stored on site.

- Emission-free: No CO₂ emissions from transport or delivery.

- Reduces traffic: Reduction in road traffic through local production.

- Security of supply: The nitrogen generated is available for production at all times.

Sustainability is a process that we are continuously developing. Together with our employees, partners and customers, we want to contribute to a better future. Let's set new standards for sustainable production together.

Contact us to find out more about our sustainable solutions!